Wood Veneer

We offer a wide selection of wood veneers, including both natural wood veneers and reconstituted veneers.

Our veneers are available in both sheets and rolls to suit various applications.

Common wood species include White Oak, Red Oak, Walnut, Teak, Maple, Ash, Cherry, Ebony, and Grey, among others.

Standard veneer thicknesses are 0.25mm, 0.4mm, and 0.5mm, with custom thicknesses available upon request.

Wood veneer plays a vital role across multiple industries, such as furniture manufacturing, wood doors, woodworking, hotel interior design, carpentry, joinery, wall paneling, and veneered plywood/MDF production.

Download PDF: 5 major types of wood veneer

Download PDF: 9 points checklist for how to choose wood veneer

5 Types of Wood Veneer Sheets and Rolls

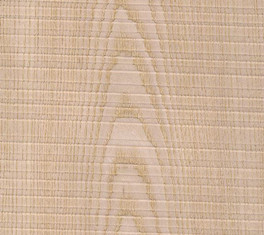

Natural Wood Veneer

Natural wood veneer is a thin slice of the real wood.

Natural wood veneers keep the original wood grains and color, and each log has different grain and color.

The most popular common natural wood species are American red oak, White oak, Walnut, European oak, Ash, Maple, Cherry, Teak, Beech, Pine, and Sapeli.

The specialty and exotic natural wood species are Rosewood, Ziricot, Burl, Crotch, Figured Maple, Bird`s eye Maple, Ebony, Tamo Ash,

For the thickness, we can cut as thin as 0.15–0.2mm, which depends on the wood species and grains.

The standard thickness is 0.4mm here in China, and some species are 0.5mm.

As for the oak, walnut, teak, 1mm, 2mm, and 3mm thick veneers are also available.

Reconstituted Wood Veneer

Reconstituted veneer—also known as recon veneer, engineered veneer, or artificial veneer—is crafted from fast-growing species such as African ayous, basswood, and poplar.

Its key advantage lies in the uniformity of color and grain across all sheets, ensuring consistency throughout your project.

In addition to classic woodgrain options like Oak, Walnut, Ebony, and Teak, a wide range of modern and exotic designs are available, including Grey, Titanium, and more.

Standard sheet dimensions are 2500 x 640 mm, but custom sizes can be produced to meet specific project needs.

We stock standard thicknesses of 0.2 mm and 0.4 mm, with custom thicknesses available up to 2 mm upon request.

Download PDF: Catalog of reconstituted wood veneer

Wood Veneer Rolls

Wood veneer rolls are finger-jointed to create continuous lengths and can be customized to your desired width.

For widths between 15mm and 60mm—commonly used for edge banding—we offer standard thicknesses of 0.4mm, as well as multi-layer options: 0.8mm (2 layers), 1mm (3 layers), 1.5mm (4 layers), and 2mm (5 layers).

For widths over 60mm, typically used for profile wrapping, we recommend our standard 0.2mm to 0.25mm thickness with a fleece backing, ideal for moulding applications.

You can choose raw veneer rolls for edge banding on doors and wood panels, or opt for our UV-prefinished veneer rolls to eliminate the need for staining and painting, saving time and labor costs.

Available backing options include fleece (non-woven fabric) and kraft paper to suit different application needs.

Download PDF: 7 types of wood veneer rolls

Backed Wood Veneer

Backed wood veneer is made by bonding real wood veneer to a backing material such as fleece (non-woven fabric) or kraft paper. This backing enhances flexibility, improves durability, and helps prevent splitting.

In addition to its functional benefits, backed veneer is also cost-effective—offering a more economical alternative to standard 0.5 mm natural veneer, making it an excellent choice for reducing overall project costs.

There are two main types of backing materials available: kraft paper and fleece (non-woven fabric), both serving as reliable support layers for the veneer.

We use both natural wood veneer and reconstituted veneer for the face layer, typically in thicknesses ranging from 0.15 mm to 0.25 mm.

The most popular options are 0.2 mm to 0.25 mm thick fleece-backed and paper-backed veneer sheets. These are widely used in interior decoration and DIY woodworking projects, as well as large-scale construction applications such as doors, cabinets, furniture, wall panels, veneered plywood, and MDF.

Exotic Wood Veneer

Exotic wood veneer is crafted from thin slices of rare and distinctive tree species, valued for their unique grain patterns, rich colors, and striking visual appeal.

Typically sourced from tropical and subtropical regions, these veneers are widely used in high-end furniture, cabinetry, luxury interiors, and architectural design projects.

Popular exotic species include Black & White Ebony, Rosewood, Ziricote, Mahogany Crotch, Walnut Crotch, Walnut Burl, Figured Veneer, Sapele Pommele, Tamo Ash, and Lacewood.

In addition to their unusual colors and grains, we can create custom-matched veneer layons in specific patterns to suit your design needs.

For a more sustainable alternative, engineered veneers are also available in a wide variety of rare grain and color options—offering the exotic look with greater consistency and eco-friendliness.

20 Related Wood Veneer Products

American Red Oak Veneer

American White Oak Veneer

American Walnut Oak Veneer

Burma Teak Wood Veneer

Reconstituted Oak Veneer

Reconstituted Walnut Veneer

Reconstituted Grey Veneer

Reconstituted Teak Veneer

Oak Veneer Edgebanding

Profile Wrapping Veneer

Fleece Backed Veneer

Paper Backed Veneer

Matched Veneer Layons

Dyed Wood Veneer

Rough Sawn Cut Veneer

Woven Veneer Sheet

Bamboo Veneer Sheet

Smoked Wood Veneer

UV prefinished Veneer Rolls

Burl Wood Veneer

In the global natural wood veneer industry, standard thicknesses typically range from 0.5mm to 0.6mm, including 0.5mm, 0.55mm, and 0.6mm.

These standard veneers are usually available from local wood veneer suppliers.

However, for special or customized veneers—particularly very thin or thick options—it’s advisable to source them from specialized suppliers in China.

For example, ultra-thin natural or engineered veneers in thicknesses such as 0.1mm, 0.15mm, 0.2mm, and 0.25mm, with or without fleece or paper backing, are more readily available from Chinese manufacturers.

We also supply thick veneers in common wood species like white oak, walnut, Burma teak, and plantation teak, with thickness options ranging from 1mm to 5mm.

Why Choose Our Wood Veneer

Download PDF : Company Presentation

Download PDF : 15 types of awesome wood veneers

Frequently Asked Questions (FAQs)

What is wood veneer?

The wood veneer is a thin slice of real wood or engineered wood. The thickness can range from 0.15mm to 0.25mm thin to max 1mm to 2mm thick.

For saw-cut veneer, the thickness can be 3mm to 5mm thick.

What are the benefits of using wood veneer?

The thin wood veneers are cost-effective and environmentally friendly. Because you can get the look and feel of solid wood at competitive prices compared with solid wood.

What substrates can I apply wood veneer to?

The common substrates are MDF, HDF, Plywood, Chipboard, and Blockboard. But it can also be applied to metal sheets, solid veneered boards, and plastics.

How should I store wood veneer?

Ideally, maintain a humidity level between 50% and 80% (RH) in areas designated for storing and handling veneer, with a recommended temperature of 20–22°C. Avoid any contact with water, liquids, condensation, or dripping on the veneer surface, even temporarily.

Store the veneer flat, elevated at least 200–250mm above the floor, and ensure it is shielded from all sources of light, both direct and indirect, to preserve its quality.

How thick/thin is the natural wood veneer?

To optimize overall costs, we typically cut thin wood veneer ranging from 0.15mm to 0.2mm. For high-end applications, veneers with thicknesses of 0.4mm to 0.5mm are often preferred. Additionally, certain specialized projects may require thicker veneers, from 1mm to 5mm, for facing plywood or MDF panels.

What is the difference between wood veneer and solid wood?

Wood veneer is a thin slice of real wood, it needs to be applied to a substrate like MDF, plywood, or particleboard.

But solid wood is made entirely from one piece of natural wood.

Where to get wood veneer?

Usually, you can find the wood veneer suppliers locally. When it is difficult to find some wood veneers from local suppliers, you can consider importing from China.

Back to top: Wood Veneer