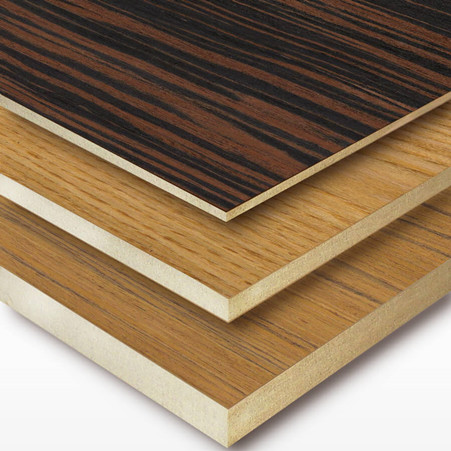

Wood Veneered Board

We offer a comprehensive range of wood veneered boards, including veneered MDF, plywood, chipboard, and blockboard.

Choose from natural wood veneer, engineered veneer, melamine, HPL, or PET for the face and back surfaces.

Board thicknesses range from 2.5mm to 25mm, with standard sizes of 1220x2440mm, 1220x2750mm, and 1220x3050mm. Customized sizes are also available.

Veneered boards provide a cost-effective and versatile alternative to solid wood, ideal for various applications such as furniture manufacturing, interior doors, hotel interiors, joinery, wall paneling, and other decorative projects.

Download PDF: 5 Major Types of Wood Veneered Board

Download PDF: 6 points checklist for how to choose wood veneered boards

5 Types of Wood Veneered Board

Wood Veneered MDF

Wood Veneered MDF is a composite board made by bonding a thin layer of wood veneer—either natural wood or reconstituted (engineered) veneer—onto the surface of an MDF (Medium Density Fiberboard) core. This combination provides the authentic look of solid wood with the stability, consistency, and cost-efficiency of MDF.

In addition to wood veneer, you can also choose melamine, HPL (High Pressure Laminate), or PET film as the face or back surface of the MDF board, depending on your design and functional needs.

Veneered MDF delivers the rich grain, natural color, and warmth of real wood, while remaining easy to cut, edge, machine, and shape—making it ideal for intricate joinery and custom interior applications.

Various MDF core options are available, including standard MDF, HDF (High Density Fiberboard), black core MDF, green HMR (moisture-resistant) MDF, and red fire-rated MDF, to meet a wide range of project requirements.

Wood Veneer Faced Plywood

Wood Veneer Faced Plywood is a plywood panel finished with a thin layer of wood veneer—either natural or engineered—applied to one or both surfaces.

Its core consists of multiple layers of wood veneers (plies) bonded together in alternating grain directions, enhancing strength and dimensional stability. The outer layer is a decorative veneer that replicates the look and texture of solid wood.

This type of plywood offers the beauty, grain, and warmth of real wood at a more economical price than solid timber. The cross-laminated structure provides excellent resistance to warping, cracking, and shrinking.

Available in various core options—such as poplar, birch, hardwood, or Okoume—and a range of thicknesses, veneered plywood can be customized to suit different project needs.

Applications include furniture production (cabinets, shelves, tables, wardrobes), as well as interior decoration such as wall paneling, ceiling finishes, partitions, and bespoke joinery.

Wood Veneered Chipboard

Veneered Chipboard is an engineered wood panel made by pressing a thin layer of wood veneer—either natural veneer or engineered wood veneer—onto the surface of chipboard (also known as particle board). The core consists of wood particles bonded with resin under heat and pressure, while the veneer layer provides a decorative, real-wood finish.

In addition to wood veneer, chipboard panels can also be finished with melamine, HPL (High Pressure Laminate), or PET film on the face or back, depending on aesthetic and performance requirements.

Compared to veneered plywood or MDF, veneered chipboard is a more economical solution, ideal for cost-sensitive projects. It is also lighter and easier to handle, making it practical for large-scale production and installation.

Applications include wardrobes, bookcases, TV units, cabinets, drawer fronts, and office or commercial furniture. It is especially popular in mass-produced and flat-pack furniture due to its affordability, versatility, and ease of machining.

Wood Veneered Blockboard

Veneered Blockboard is an engineered wood panel featuring a decorative wood veneer surface bonded to a blockboard core.

The core is composed of solid softwood strips—typically pine, poplar, or falcata—edge-glued and sandwiched between veneer or thin wood layers, providing excellent strength and dimensional stability. The veneered surface replicates the natural beauty of solid wood.

In addition to wood veneer, blockboard panels can also be finished with melamine, HPL (High Pressure Laminate), or PET film on the face or back, depending on design preferences and performance needs.

Compared to plywood, veneered blockboard is lighter in weight, making it easier to transport, handle, and install—especially suitable for large furniture pieces or vertical applications. It also offers strong screw-holding capacity, making it ideal for carpentry and joinery projects that require secure fastening.

Customized Wood Veneered Boards

Customized Wood Veneered Boards are specially engineered wood panels tailored to meet your design specifications.

You can combine different core materials—such as MDF, plywood, blockboard, or even aluminum sheets—to achieve the desired performance and structure.

These boards are created based on the imagination and requirements of designers, transforming creative concepts into functional and visually striking materials.

Beyond the core structure, surface customization is also available. You can select from a wide range of wood veneer species, and add unique textures, patterns, or finishes to match your design vision.

Ideal for bespoke furniture, interiors, and architectural projects, customized veneered boards offer both creative freedom and practical performance in one engineered solution.

20 Related Veneered Wood Boards

Oak Veneered MDF

Walnut Veneered MDF

Ash Veneered MDF

Melamine Faced MDF

Oak Faced Plywood

Walnut Faced Plywood

Teak Faced Plywood

Pine Faced Plywood

Oak Veneer Chipboard

Beech Veneered Chipboard

Melamine Faced Chipboard

White Chipboard

Pine Blockboard

Oak Veneer Blockboard

Falcata Blockboard

Melamine Blockboard

Bamboo Board

Thick Veneered Board

Milled Veneer Board

Custom Wall Board

In the 1980s, China’s decorative board industry was small and workshop-based. With reform and opening-up, the sector began to grow rapidly.

By the 21st century, it entered a transformation phase, with companies focusing on branding, quality, and service. Products evolved toward high-end, eco-friendly, and intelligent development.

Today, China is one of the world’s largest producers and consumers of decorative panels, driven by rising demand in construction, home furnishing, and automotive sectors.

The market is expected to grow steadily, increasing from 85 billion yuan in 2025 to about 120 billion yuan by 2030, with a CAGR of 7%–8%.

Why Choose Our Wood Veneered Boards

Download PDF : Company Presentation

Download PDF : 15 types of awesome wood veneers

Frequently Asked Questions (FAQs)

What are wood veneered boards?

Wood veneered boards are engineered wood panels (like MDF, plywood, or particle board) covered with a thin layer of wood veneer, melamine, PET to give the appearance of solid wood.

What types of core materials are used for veneered boards?

Common cores include MDF, plywood, chipboard (particleboard), and blockboard.

What is the difference between veneered boards and solid wood?

Veneered boards use a thin layer of wood veneer on a stable substrate, while solid wood is a single piece throughout. Veneered boards are more cost-effective.

What thickness of veneers for boards?

Ideally, 0.2mm thin and common 0.4mm/0.5mm wood veneers are common for veneered wood boards. But you can also request 1mm, 2mm, 3mm, even 5mm thick wood veneers to be the face/back of wood boards.

Can wood veneered boards be painted or stained?

They can be stained (since they use real wood veneer), but color painting may hide the wood grain, which defeats their aesthetic purpose.

Can I customize the wood species or surface pattern?

Yes. Many manufacturers offer natural, reconstituted/engineered veneers in various grains and colors. And you can also choose the melamine and PET.

Where to find veneered board factories in China?

Linyi city is the most famous wood board production base city in China.

Back to top: Wood Veneered Board