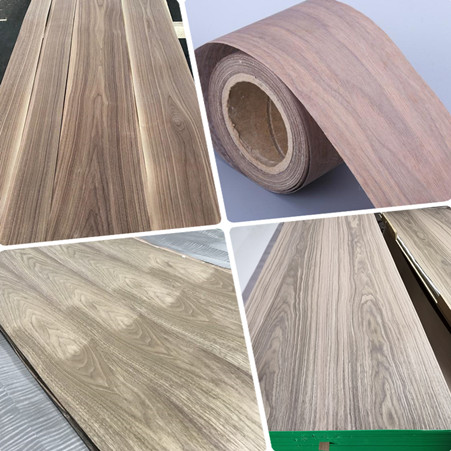

Walnut Veneer

Natural American Walnut veneer is one of the most popular dark wood veneers used worldwide, valued for its rich color and elegant grain.

It is available in walnut veneer sheets, veneer rolls, and matched layon to suit different design and production needs.

For easy handling and lamination, thin walnut veneers are offered in 0.2 mm fleece-backed or paper-backed options.

Standard stock thicknesses include 0.4 mm, 0.5 mm, 1 mm, and 2 mm.

In addition to these common sizes, we also supply 3 mm and 5 mm sawn-cut walnut veneer sheets for projects requiring extra depth and durability.

We further provide walnut-veneered plywood, walnut wall panels, and walnut veneer-wrapped molding profiles for complete interior solutions.

Download PDF: 5 major types of wood veneer

Download PDF: Technical Data Sheet of Walnut Veneer

Download PDF: 9 points checklist for how to choose wood veneer

12 Types of American Walnut Veneer Products

0.2mm thin Fleece/Paper Backed Walnut Veneer

Fleece or Paper backed walnut veneer is crafted by bonding natural American walnut veneer onto a flexible backing material such as fleece (non-woven fabric) or kraft paper.

Those added layers enhance the veneers’ flexibility, durability, and resistance to splitting, making them easier to handle and apply.

Beyond their performance benefits, backed walnut wood veneer is also a cost-effective alternative to standard 0.4mm or 0.5mm natural walnut veneers, helping to reduce overall project costs.

We offer two main types of backing materials—kraft paper and fleece—both give strong and stable support for the veneer surface.

Among the most popular options are 0.2mm fleece-backed and paper-backed veneer sheets, widely used in moulding profile wrapping, furniture making, cabinetry, wall paneling, and veneered plywood and MDF.

0.4 & 0.5mm American Walnut Veneer

In China, 0.4 mm natural walnut veneer is the standard thickness widely stocked in the domestic veneer market.

Some veneer slicing factories also keep 0.5 mm walnut veneer available, mainly to meet export demands.

For furniture production and standard 4 × 8 ft veneered plywood or MDF, random veneer lengths typically start from 2500 mm and above.

In veneered door manufacturing, lengths of 1800 mm and longer are commonly used.

Veneer sheets shorter than 1800 mm are often applied for edge banding or assembled into matched walnut veneer layons.

A variety of grain patterns is available, including flat-cut (crown-cut), quarter-cut, rift-cut, and half-crown walnut veneer sheets, each offering a unique texture and visual appeal.

1 & 2mm thick Walnut Veneer

When producing high-end walnut cabinets, furniture, or bespoke woodwork, many craftsmen like to choose thick walnut veneers for their superior texture, depth, and workability.

To meet this demand, we keep stocks of 1 mm and 2 mm American walnut veneers, available in random lengths over 2500 mm and widths above 100 mm.

Compared with standard thin walnut veneers, thicker walnut veneers deliver greater durability, richer grain definition, and a more authentic solid-wood appearance.

Although they cost more than thinner options, their superior strength, visual depth, and finishing performance make them a worthwhile investment.

These premium thick walnut veneers are widely used in luxury furniture, cabinetry, and architectural detailing, where natural beauty and long-lasting quality are essential.

3 & 5mm American Walnut Veneer Sheet

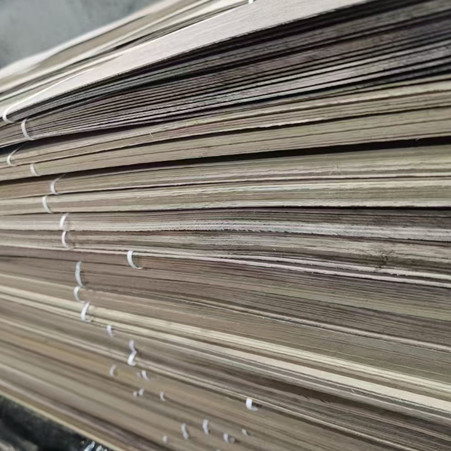

3mm and 5mm thick American walnut veneer sheets are edge-spliced veneer panels crafted from sawn-cut natural walnut veneers.

These thick walnut veneers are carefully edge-joined to form 4×8 ft, 4×9 ft, or 4×10 ft sheets, offering both strength and beauty for fine woodworking applications.

The 3mm walnut veneer sheets are ideal for luxury cabinet doors, furniture surfaces, and other high-end joinery projects, providing a rich, natural wood texture.

Meanwhile, 5mm thick walnut veneer sheets can be laminated onto plywood or MDF to create milled or decorative wall panels, adding depth and elegance to interior spaces.

Their substantial thickness ensures excellent durability, surface stability, and a sophisticated real-wood finish suitable for custom architectural designs.

Reconstituted Walnut Veneer

Reconstituted walnut veneer—also known as recon walnut veneer, engineered walnut veneer, or artificial walnut veneer—is made from fast-growing African wood ayous.

Its greatest advantage is the uniformity of color and grain, ensuring a consistent, high-quality appearance across every sheet—ideal for large-scale or precision design projects.

We offer reconstituted veneers in various grain styles, including fineline, flat cut, quarter cut, and rift cut options.

Standard sheet sizes are 2500 x 640 mm, with custom length and width available to suit specific design requirements.

Our standard stock thicknesses are 0.2 mm and 0.4 mm, while custom thicknesses up to 5 mm can be produced upon request for specialized applications.

Download PDF: Catalog of reconstituted wood veneer

Spliced Walnut Wood Veneer Sheet

Spliced walnut veneer is an edge-jointed walnut veneer sheet created by joining individual walnut veneer leaves through edge gluing or thread splicing.

By carefully matching these walnut leaves, you can get book match, slip match, or random match patterns. For creative woodworking designs, architects often choose decorative options like diamond, herringbone, or sunburst matches.

These matched walnut veneers are commonly used for custom door or wall panels, offering tailored veneer sheets in various sizes and patterns.

Among them, spliced walnut veneer stands out as a top choice for interior decoration, valued for its warm tone, natural grain, and design versatility.

It’s a perfect blend of precision craftsmanship and aesthetic appeal for modern furniture and architectural applications.

Walnut Veneer Rolls for Edge banding and Profile Wrapping

Walnut wood veneer rolls are produced by finger-jointing natural walnut veneer strips to form continuous rolls with virtually unlimited length.

Standard thicknesses range from 0.2 mm up to 2 mm, and all walnut veneer rolls are reinforced with fleece or paper backing to improve flexibility, stability, and durability.

After finger-jointing, the walnut veneer rolls are precision-slit to custom widths, making them ideal for veneered doors, frames, skirting boards, and moulding profiles.

TWalnut veneer rolls provide the authentic beauty and texture of solid walnut while significantly reducing material costs.

Beyond traditional applications like architraves and cornices, walnut veneer rolls are also used for laminating aluminium panels, tubes, and other interior fit-out or joinery projects, offering both versatility and elegance.

Walnut Burl Veneer

Walnut burl veneer is a highly decorative wood veneer famous for its unique burl grain, rich color variation, and natural, organic character.

Formed from the burl growth of walnut trees, each sheet features unique eyes, curls, and intricate patterns that cannot be replicated, making every application one of a kind.

Walnut burl veneer is commonly used in luxury furniture, feature walls, cabinetry, doors, and high-end interior panels where visual impact is essential.

Available in natural, spliced, or lay-on formats, walnut burl veneer can be supplied in various thicknesses and backing options to suit different fabrication needs.

Combining rare natural beauty with refined craftsmanship, walnut burl veneer adds depth, elegance, and a sense of exclusivity to premium architectural and furniture designs.

Woven Walnut Veneer

Walnut woven veneer is a decorative surface material crafted from natural walnut veneer or reconstituted walnut veneer, offering a distinctive blend of artistry and wood texture.

Selected walnut veneer strips are precisely cut and carefully hand-woven into intricate patterns, then laminated with kraft paper or fleece (non-woven fabric) backing to ensure excellent flatness, flexibility, and durability during application.

As a fully handcrafted product, walnut woven veneer highlights both craftsmanship and natural beauty, making it ideal for high-end furniture, cabinet doors, wall panels, hotel interiors, and other luxury decorative surfaces.

It is available in standard or custom weave designs, with typical thicknesses of 0.5 mm and 0.8 mm, and maximum sheet sizes up to 2500 × 1250 mm.

Custom dimensions can be produced to meet specific project requirements.

Walnut Veneered Board

Besides the walnut veneers, we also supply walnut veneered boards to our clients.

You can choose the substrate as Plywood, MDF, Blockboard, Particle board, or Solid wood boards.

For the faced walnut veneers, you can select 0.2mm, 0.4mm, 0.5mm, 1mm, 2mm.

Board thicknesses are available from 2.5 mm to 25 mm, with standard dimensions of 1220 × 2440 mm (4×8 ft), 1220 × 2750 mm (4×9 ft), and 1220 × 3050 mm (4×10 ft). Custom sizes can also be produced upon request.

Offering the warmth and texture of real wood at a more affordable cost, natural walnut veneered boards are perfect for furniture making, interior doors, wall panels, hotel interiors, joinery work, and other decorative architectural applications.

And you can also consider our 5mm thick walnut veneered panels with milled grains and patterns for wall covering and cabinet manufacturing.

Walnut Veneered Moulding Profiles

We supply a wide range of walnut veneered moulding profiles designed for interior decoration, doors, architraves, wall cladding, and picture frames.

Options include natural walnut veneer-wrapped and solid walnut mouldings in styles such as crown, baseboard, casing, chair rail, and handrail.

Wrapped mouldings combine decorative walnut veneers with various core materials for flexible design and cost control. Veneer options include natural walnut and reconstituted walnut, while core materials include finger-joint solid wood, MDF, HDF, plywood, or aluminum alloy.

Using advanced wrapping technology and PUR hot melt adhesives, walnut veneers are precisely bonded for long-lasting adhesion and durability.

For added efficiency, we also offer UV-prefinished veneer rolls, providing a smooth, ready-to-use surface that reduces staining and finishing costs.

Walnut Veneered Wall Panel

We offer a comprehensive range of walnut wall solutions, including solid walnut wall panels, fluted walnut panels, milled walnut panels, and flexible tambour walnut wall panels.

From modern fluted designs and vertical slat panels to classic tongue-and-groove wall systems, our walnut panels add warmth, depth, and character to any interior space.

For functional performance, acoustic walnut wall panels help improve sound control, while striking 3D walnut panels and tambour panels create bold visual statements.

In addition to natural walnut veneer, we also provide PVC walnut, paper walnut, and reconstituted walnut veneer options to suit different budgets and applications.

If you require customized walnut wall panels in specific sizes, profiles, or finishes, please feel free to contact our sales team for professional support and tailored solutions.

In the global walnut veneer market, standard thicknesses typically range from 0.5 mm to 0.6 mm, including commonly used options such as 0.5 mm, 0.55 mm, and 0.6 mm.

These standard specifications are widely available from local suppliers worldwide and are suitable for most conventional applications.

For special or customized thickness requirements—particularly ultra-thin or thick walnut veneers—it is recommended to source from specialized manufacturers in China.

Advanced veneer slicing and lamination technologies enable higher precision and consistent quality.

We supply ultra-thin walnut veneers in 0.15 mm, 0.2 mm, and 0.25 mm, with optional fleece or paper backing for enhanced flexibility and strength.

In addition, we offer thick walnut veneers from 1 mm up to 5 mm to meet diverse design and performance needs.

Why Choose Our Walnut Wood Veneer

Download PDF : Company Presentation

Download PDF : 15 types of awesome wood veneers

Frequently Asked Questions (FAQs)

Q1. What is walnut veneer?

A1. Walnut veneer is a thin slice of real walnut wood, produced by slicing or sawing logs, and used to surface furniture, panels, doors, and interiors while retaining the natural walnut grain and color.

Q2. What thicknesses are available for walnut veneer?

A2. Standard walnut veneer thicknesses are 0.4 and 0.5 mm. Ultra-thin options (0.15–0.2 mm) and thick veneers (1–5 mm) are also available for special applications.

Q3. What types of walnut veneer are available?

A3. Common options include natural walnut veneer, engineered (reconstituted) walnut veneer, burl walnut veneer, woven walnut veneer, spliced veneer sheets, and walnut veneer rolls.

Q4. What are walnut veneer rolls used for?

A4. Walnut veneer rolls are ideal for edge banding, door frames wrapping, skirting boards, molding profiles, and wrapping curved or long surfaces.

Q5. What is the difference between natural and reconstituted walnut veneer?

A5. Natural walnut veneer offers unique, organic grain variations, while reconstituted walnut veneer provides consistent color and pattern, making it easier to match across large areas.

Q6. What walnut wall panels can you supply?

A6. Walnut wall solutions include solid walnut panels, fluted walnut panels, slat panels, milled panels, acoustic panels, tambour panels, and 3D decorative panels.

Q7. Are walnut wall panels suitable for acoustic treatment?

A7. Yes. Acoustic walnut wall panels with perforated boards or slat designs help improve sound absorption in offices, hotels, theaters, and residential spaces.

Q8. Can walnut wall panels be customized?

A8. Absolutely. Panel size, thickness, profile, veneer type, backing material, finish, and color can all be customized to meet project requirements.

Back to top: Walnut Veneer